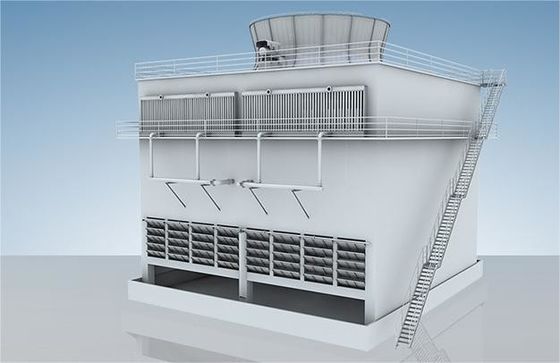

500m3/H-4500m3/H Forced Draft Counterflow Cooling Tower Open Circuit Cooling Tower

Working Principle:

Hot water enters the cooling tower from the top, usually through pipes.

A fan or other ventilation equipment at the bottom of the tower introduces cooling air to the bottom of the cooling tower.

The hot water flows through the packing layer and exchanges heat with the rising cooling air.

The heat in the hot water is transferred to the air, causing the water temperature to drop, while the air heats up and removes the heat.

Application Areas:

Counterflow open cooling towers are widely used in power plants, chemical plants, refineries and other industrial sites to cool circulating water, coolants or other hot water or fluids generated by the production process.

These cooling towers help maintain the normal operating temperature of industrial equipment and reduce heat emissions from the production process.

Maintenance and Performance Optimization:

Counterflow open cooling towers require regular maintenance, including cleaning the packing, checking the pipes and valves, etc.

Optimizing the performance of the cooling tower can be achieved through proper packing selection, fan adjustment and fluid circulation control to ensure the best heat exchange efficiency.

Product Specification:

| type |

water capacity m³/h |

exterior size |

fan |

water inlet pipe DN(mm) |

water distribution pipe height mm |

other size |

weight |

standard spot noise dB(A) |

|||||||||

| B(mm) |

H(mm) |

diameter mm |

air volume x10^4m³ |

motor power N(KW) |

B1 |

L |

H₁ |

H₂ |

A |

dry t |

concret size m3 |

wet t |

|||||

| 10NH-500 |

500 |

6400 |

9200 |

4000 |

32.4 |

22 |

350 |

5200 |

3200 |

19200 |

2700 |

6500 |

2121 |

15.4 |

24 |

91.8 |

≤75 |

| 10NH-750 |

750 |

7800 |

10376 |

5000 |

48 |

30 |

450 |

5750 |

3900 |

23400 |

3200 |

7300 |

2352 |

22.1 |

29 |

118.2 |

≤75 |

| 10NH-1000 |

1000 |

9000 |

11555 |

6000 |

64 |

45 |

500 |

6300 |

4500 |

27000 |

3700 |

7900 |

2526 |

28.4 |

36 |

148.4 |

≤75 |

| 10NH-1500 |

1500 |

11000 |

13228 |

7000 |

96 |

75 |

600 |

7150 |

5500 |

33000 |

4200 |

9200 |

4784 |

40.3 |

60 |

235.6 |

≤75 |

| 10NH-2000 |

2000 |

12800 |

14500 |

8000 |

130 |

92 |

700 |

7250 |

6400 |

38400 |

4500 |

9750 |

5184 |

53.9 |

77 |

306.9 |

≤75 |

| 10NH-2500 |

2500 |

14400 |

14550 |

8530 |

157 |

110 |

800 |

7250 |

7200 |

43200 |

4500 |

9750 |

5034 |

65.7 |

100 |

409.3 |

<75 |

| 10NH-3000 |

3000 |

15800 |

15350 |

8530 |

190 |

132 |

900 |

7500 |

7900 |

47400 |

4700 |

10550 |

5534 |

77.6 |

120 |

473.2 |

≤75 |

| 10NH-3500 |

3500 |

17000 |

15400 |

8530 |

218.5 |

160 |

900 |

7600 |

4250 |

34000 |

5000 |

10600 |

5584 |

86.5 |

180 |

651 |

≤75 |

| 10NH-4000 |

4000 |

18200 |

16112 |

9140 |

252 |

185 |

1000 |

7800 |

4550 |

36400 |

5200 |

11050 |

5734 |

99.1 |

200 |

728.5 |

≤75 |

| 10NH-4500 |

4500 |

19300 |

16712 |

9140 |

282 |

220 |

1000 |

8100 |

4825 |

38600 |

5500 |

11650 |

6034 |

109 |

220 |

805.1 |

≤75 |

|

design condition: wb temp=28℃ barometric pressure=1.004x10^5 Pa inlet water temp=43℃ outlet water temp=33℃ |

note: 1.The weight of the equipment is calculated in units of a single tower 2.the dry weight is the weight of the delivery product,concrete size is the concrete structure 3.Specific gravity of concrete is calculated at 2.6t/m³,wet weight is the tower operation weight |

||||||||||||||||

![]()

![]()