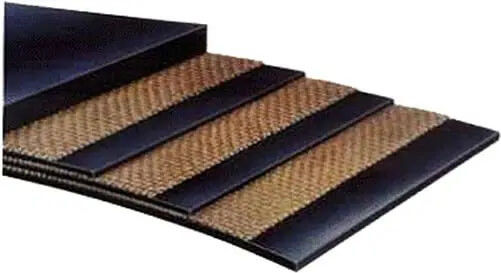

Polyester EP Conveyor Belt General Temperature Conveyor Belting

Product Feature:

1. Fabric Construction: EP fabric conveyor belts are constructed using multiple layers of polyester (EP) or nylon fabric. These fabric layers provide the belt with excellent tensile strength, flexibility, and durability.

2. EP Strength: The term "EP" stands for "ethylene propylene," which refers to the type of synthetic fabric used in the belt's construction. EP fabric belts are known for their high strength-to-weight ratio, making them capable of handling heavy loads and providing reliable performance.

3. Cover Materials: EP fabric conveyor belts typically have a protective cover on the top and bottom surfaces, which serves to enhance the belt's resistance to wear, impact, and abrasion. The cover materials can vary depending on the specific application and may include rubber, PVC, or other specialized compounds.

4. Belt Width and Length: EP fabric conveyor belts are available in various widths and lengths to suit different conveyor systems and application requirements. The selection of the belt width depends on factors such as the material being conveyed, the conveyor design, and the desired throughput.

5. Suitable for Normal Temperatures: EP fabric conveyor belts are designed to operate within a temperature range considered normal for most industrial environments. Typically, these belts can handle temperatures ranging from -30°C to +80°C (-22°F to +176°F), although specific variations may have different temperature limits.

6. Splice Options: EP fabric conveyor belts can be joined using various splice methods, including mechanical fasteners or vulcanized splicing. The choice of splice method depends on factors such as the belt width, belt thickness, application conditions, and the desired strength and durability of the splice.

7. Customization Options: EP fabric conveyor belts can be customized to meet specific application requirements. This includes selecting the appropriate belt grade, cover compound, and fabric ply configuration based on factors such as the conveyed material, conveyor system design, and operating conditions.

Product Specification:

| Polyester Multi Layer Conveyor Belt Parameter | ||||||||||

| fabric type | fabric construction | Fabric model | Tape thickness | Strength series(N/mm) | Covering glue thickness(mm) | width range(mm) | ||||

| Longitude | latitude | 2层 | 3层 | 4层 | Cover glue | Lower cover glue | ||||

| polyester(EP) | polyester | Nylon | EP-80 | 1.00 | 160 | 240 | 320 | 0~12 | 0~10 | 300~6000 |

| EP-100 | 1.00 | 200 | 300 | 400 | ||||||

| EP-125 | 1.05 | 250 | 375 | 500 | ||||||

| EP-150 | 1.10 | 300 | 450 | 600 | ||||||

| EP-170 | 1.10 | 340 | 510 | 680 | ||||||

| EP-200 | 1.20 | 400 | 600 | 800 | ||||||

| EP-250 | 1.40 | 500 | 750 | 1000 | ||||||

| EP-300 | 1.60 | 600 | 900 | 1200 | ||||||

| EP-350 | 1.70 | 1050 | 1400 | |||||||

| EP-400 | 1.90 | 1600 | ||||||||

| EP-500 | 2.10 | 2000 | ||||||||

| Polyadhesive strength elongation performance compliance table | |||||

| Core material | between fabric layers N/mm | Between covering layer and cloth layerN/mm | Extended performance | ||

| Cover thickness≤1.5mm | Cover thickness≥1.5mm | Full thickness longitudinal tensile elongation at break | Full thickness longitudinal reference force elongation | ||

| polyester canvas | ≥5 | ≥4.5 | ≥5 | ≥10% | ≤4% |

| Tape cover properties | |||||

| Coverage level | Tensile Strength | Elongation at break | Amount of wear | Change rate of tensile strength and elongation at break after aging | |

| MPA | Kgf/cm2 | % | Mm3 | % | |

| H | 24 | 240 | 450 | 120 | -25~+25 |

| D | 18 | 180 | 400 | 100 | -25~+25 |

| L | 15 | 150 | 350 | 200 | -25~+25 |