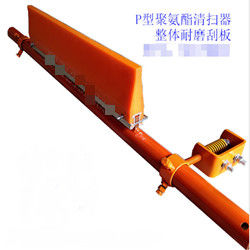

Self-Adjusting P Secondary Belt Cleaners Conveyor Belt Scraper Wear-Resistant

Product Description:

The function of the ‘P’ Series Secondary Conveyor Belt Cleaner is to remove fine and sticky materials from the belt at the point of discharge, after the Primary ‘H’ Series Belt Cleaner has removed the course carryback. It prevents the fine sticky material from building up on the return conveyor rollers and support structures, as well as assisting with the provision of a clean and safe working environment for the bulk materials handling.

Product Specification:

| Model | P-500 | P-650 | P-800 | P-1000 | P-1200 | P-1400 | P-1600 | P-1800 | P-2000 | P-2200 |

| Belt width (mm) | 500 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

| Integral scraper (mm) | 450 | 600 | 800 | 900 | 1200 | 1350 | 1500 | 1800 | 1950 | 2100 |

Product Advantage:

1. Fine Particle Removal: P Secondary Belt Cleaners are specifically designed to remove fine particles, dust, and residual material that may remain on the conveyor belt after the primary cleaning process. They effectively target and clean off the smaller particles that the primary cleaner may have missed, ensuring a clean and debris-free belt surface.

2. Material Carryback Reduction: By removing fine particles and residual material, P Secondary Belt Cleaners help minimize material carryback on the belt. Carryback can lead to issues such as belt slippage, material buildup on idlers and pulleys, and potential contamination of the conveyed material. The secondary cleaner improves overall material containment and reduces the need for manual cleanup and maintenance.

3. Improved Conveyor Performance: The use of P Secondary Belt Cleaners contributes to improved conveyor performance. By maintaining a clean belt surface, they help prevent belt slippage, reduce the risk of belt mistracking, and ensure proper material flow. This results in enhanced productivity, reduced downtime, and increased overall efficiency of the conveyor system.