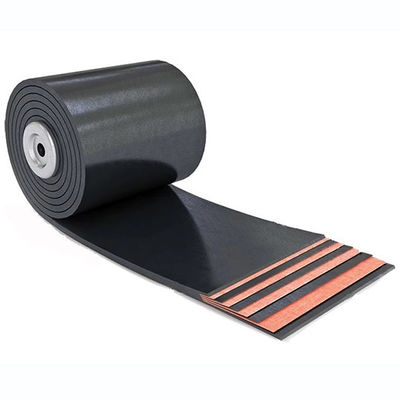

NN EP Rubber Conveyor Belt Polyester Nylon Conveyor Belts Wear Resistant

Product Description:

NN EP Rubber Conveyor Belts commonly have three layers: a top cover, a carcass and a bottom cover. The Carcass is made of synthetic EP or NN fabric, provide longitudinal strength and shape.Cover rubber includes top cover and bottom rubber, are designed to protect the carcass from abrasion and impact.

With the advantages of light weight, high-strength, good impact resistance, excellent troughability, low elongation and good impact stability ever heated, it is the developing trend of fabric conveyor belt.

Specification:

| Polyester Multi Ply Conveyor Belt Parameter | ||||||||||

| fabric type | fabric construction | Fabric model | Tape thickness | Strength series(N/mm) | Covering glue thickness(mm) | width range(mm) | ||||

| Longitude | latitude | 2 Ply | 3 Ply | 4 Ply | Cover glue | Lower cover glue | ||||

| polyester(EP) | polyester | Nylon | EP-80 | 1.00 | 160 | 240 | 320 | 0~12 | 0~10 | 300~6000 |

| EP-100 | 1.00 | 200 | 300 | 400 | ||||||

| EP-125 | 1.05 | 250 | 375 | 500 | ||||||

| EP-150 | 1.10 | 300 | 450 | 600 | ||||||

| EP-170 | 1.10 | 340 | 510 | 680 | ||||||

| EP-200 | 1.20 | 400 | 600 | 800 | ||||||

| EP-250 | 1.40 | 500 | 750 | 1000 | ||||||

| EP-300 | 1.60 | 600 | 900 | 1200 | ||||||

| EP-350 | 1.70 | 1050 | 1400 | |||||||

| EP-400 | 1.90 | 1600 | ||||||||

| EP-500 | 2.10 | 2000 | ||||||||

![]()

Common EP Conveyor Belt Type:

2 Ply Conveyor Belt: EP315/2 EP400/2 EP500/2 EP630/2 EP800/2

3 ply conveyor belt: EP400/3 EP500/3 EP630/3 EP800/3 EP1000/3 EP1250/3

5 ply conveyor belt: EP800/5 EP1000/5 EP1250/5 EP1600/5 EP2000/5

| Polyadhesive strength elongation performance compliance table | |||||

| Core material | between fabric layers N/mm | Between covering layer and cloth layerN/mm | Extended performance | ||

| Cover thickness≤1.5mm | Cover thickness≥1.5mm | Full thickness longitudinal tensile elongation at break | Full thickness longitudinal reference force elongation | ||

| polyester canvas | ≥5 | ≥4.5 | ≥5 | ≥10% | ≤4% |

| Tape cover properties | |||||

| Coverage level | Tensile Strength | Elongation at break |

Amount of wear |

Change rate of tensile strength and elongation at break after aging | |

| MPA | Kgf/cm2 | % | Mm3 | % | |

| H | 24 | 240 | 450 | 120 | -25~+25 |

| D | 18 | 180 | 400 | 100 | -25~+25 |

| L | 15 | 150 | 350 | 200 | -25~+25 |

Types:

Besides General-used EP conveyor belt, there are Fire-retardant type, Cold-resistant type, Wear-resistant type, Heat-resistant type, Acid and alkaline resistant type, Oil-resistant type, Antistatic electricity type, High-grade type and etc.

Application:

Applicable to long-distance, high capacity, high-speed delivery of materials under the conditions.

Used in mining, quarries, chemical plants, architectural industry and etc.it is used for material transportation in chemical industry, electric power, metallurgy, light industry, grain processing, coal mine and other industries.

![]()